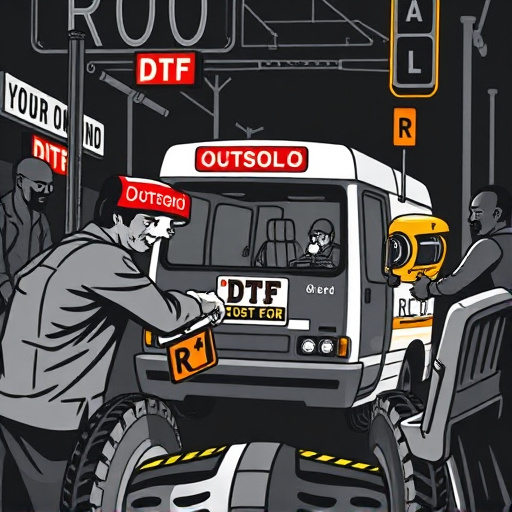

Direct-to-Film (DTF) transfers are revolutionary in printing, offering high-quality, scratch-resistant images on various surfaces like vinyl and fabric. Key factors affecting their durability include film quality, applicator skill, surface preparation, and environmental conditions. Optimal storage conditions, premium materials, and thickness extend DTF transfer lifespans up to 5-7 years outdoors, surpassing traditional printing methods as proven by successful case studies in industries like outdoor advertising, fashion, and automotive. Regular cleaning and protective measures further preserve their vibrancy.

Direct-to-film (DTF) transfers have revolutionized graphic applications, offering vivid prints directly onto various surfaces. Yet, understanding their durability is crucial for long-term performance. This article delves into the key factors influencing DTF transfer lifespan. From environmental conditions and material quality to care and maintenance tips, we explore what determines the longevity of these transfers. Real-world case studies further highlight effective strategies for maximizing DTF transfer durability.

- Understanding Direct-to-Film (DTF) Transfers: A Brief Overview

- Key Factors Influencing DTF Transfer Durability

- Environmental Conditions and Their Impact on Lifespan

- Material Quality and Thickness: A Closer Look

- Care and Maintenance for Extended Lifespan

- Real-World Application and Case Studies

Understanding Direct-to-Film (DTF) Transfers: A Brief Overview

Direct-to-Film (DTF) transfers are a cutting-edge method in the printing industry, offering an innovative way to create long-lasting, high-quality images directly on various surfaces, from vinyl to fabric. This process involves transferring ink or dye onto the substrate using specialized equipment, eliminating the need for intermediate rollers or plates. The result is a crisp, vibrant image with exceptional durability.

DTF Transfers stand out due to their ability to provide a durable, scratch-resistant finish that can withstand everyday use. The lifespan of these transfers varies based on factors like material quality, printing technique, and environmental conditions, but they are designed to last for years without significant fading or damage. This makes DTF Transfers ideal for applications in outdoor advertising, fashion, and even automotive industries, where longevity and vibrancy are paramount.

Key Factors Influencing DTF Transfer Durability

Several key factors play a significant role in determining the durability of Direct-to-Film (DTF) transfers. One of the primary considerations is the quality and composition of the film itself. Using high-grade, durable materials significantly enhances the longevity of the transfer. The expertise of the applicator is another critical aspect; proper application techniques, including careful handling and precise printing, ensure that the DTF is laid evenly and securely on the surface.

Environmental conditions also exert a considerable influence. Factors such as temperature, humidity, and exposure to sunlight can accelerate degradation over time. Therefore, ideal storage conditions are essential to preserve the transfer’s integrity. Additionally, the surface preparation is vital; a clean, smooth base ensures better adhesion and protects against peeling or cracking.

Environmental Conditions and Their Impact on Lifespan

The longevity of a direct-to-film (DTF) transfer significantly depends on the environmental conditions it is exposed to. Factors such as temperature, humidity, and sunlight play a pivotal role in determining the lifespan of these transfers. Extreme heat can cause the transfer to deteriorate faster, while excessive moisture can lead to fading and peeling. Prolonged exposure to direct sunlight is another major contributor to the deterioration of DTF transfers, as UV rays break down the adhesive and ink, resulting in loss of quality and color accuracy over time.

Maintaining optimal storage conditions is crucial for preserving the integrity of DTF transfers. Cool, dry environments with minimal light exposure are ideal. Proper care includes storing the transfers away from direct sunlight, heat sources, and high humidity areas. By understanding and mitigating these environmental factors, users can expect their DTF transfers to maintain their quality and vibrancy for an extended period.

Material Quality and Thickness: A Closer Look

The quality and thickness of materials used in Direct-to-Film (DTF) transfers play a significant role in determining their longevity. Higher-quality materials, such as premium vinyl or heat-transfer papers, offer better durability compared to lower-grade options. These top-tier materials are often thicker, providing added protection against wear and tear. Thicker substrates can withstand more use and abuse, making them ideal for items that see frequent handling or exposure to harsh conditions.

When selecting DTF transfers, paying attention to material specifics is crucial. Manufacturers typically provide guidelines on recommended thicknesses and material types for various applications, ensuring the best performance and extended lifespans. Using materials of inferior quality may result in shorter-lived transfers, with potential issues like fading, cracking, or peeling emerging sooner than expected.

Care and Maintenance for Extended Lifespan

To maximize the lifespan of a Direct-to-Film (DTF) transfer, proper care and maintenance are essential. Regular cleaning is crucial to prevent dirt, dust, and other debris from accumulating on the film surface, which can degrade its quality over time. Use mild soap and warm water to gently clean the transferred image area, avoiding abrasive materials that could scratch the film. Additionally, storing the DTF transfer in a cool, dry place, away from direct sunlight and extreme temperatures, will help prevent fading and damage.

Consider using protective covers or frames to shield the transfer from physical impacts and environmental factors. Avoiding moisture and excessive heat is vital for preserving the vividness and clarity of the image. Regularly inspecting the DTF transfer for any signs of wear or damage and taking proactive measures to address them will contribute to its extended lifespan, ensuring that your cherished memories remain vibrant and intact for years to come.

Real-World Application and Case Studies

Direct-to-film (DTF) transfer technologies have proven their durability in real-world applications, with numerous case studies highlighting their longevity. From outdoor advertising billboards to transportation fleets, DTF transfers have withstood harsh environmental conditions, including constant exposure to sunlight, rain, and pollution. These materials are designed to maintain their vibrancy and integrity for extended periods, often outperforming traditional printing methods.

Case studies conducted by leading industry players show that DTF transfers can last up to 5-7 years outdoors without significant color fading or degradation, depending on the quality of the material and the specific environmental factors. For instance, a study by a major transport company revealed that DTF-printed wraps on buses retained over 90% of their original color after two years, offering a cost-effective and visually appealing solution for vehicle advertising.